ERP system for supply chain management stands as a cornerstone for modern businesses aiming to navigate the complexities of global commerce. This powerful technology offers a unified approach to managing diverse operational facets, from procurement and inventory to logistics and customer relations. By integrating these critical functions, an ERP system transforms how companies perceive and interact with their supply chains, fostering unprecedented levels of efficiency and insight.

Prepare to explore the profound impact of ERP on optimizing every link in the chain, ensuring resilience and driving growth in an ever-evolving marketplace.

This comprehensive guide delves into the foundational principles of integrating an enterprise resource planning system into supply chain operations. We will explore the core functionalities that enhance visibility and control, detailing how ERP consolidates disparate data into a single, accessible platform. Furthermore, we will examine the essential modules critical for effective supply chain management, such as procurement, inventory, warehousing, and logistics, alongside the strategic advantages of aligning ERP capabilities with overarching supply chain objectives.

Fundamental Principles of ERP Integration in Supply Chain Management: Erp System For Supply Chain Management

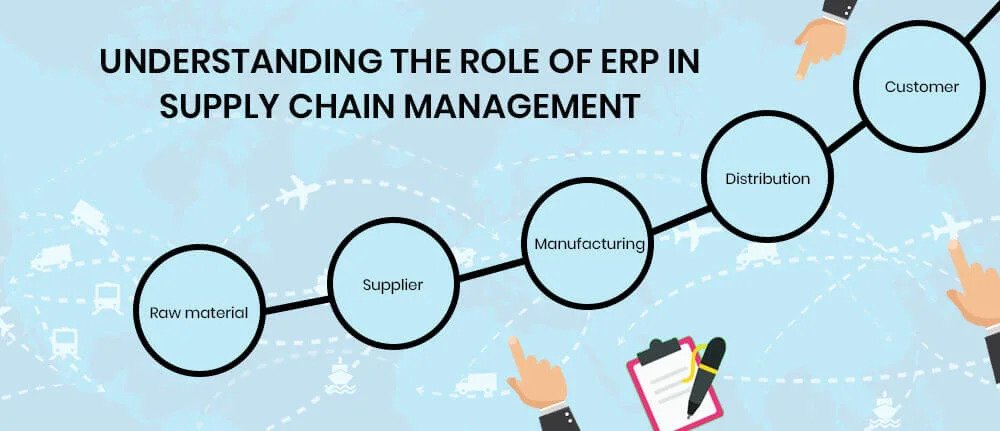

Integrating an Enterprise Resource Planning (ERP) system into the complex web of supply chain operations is not merely about adopting new software; it’s a strategic imperative that redefines how businesses manage the flow of goods, information, and finances from origin to consumption. At its core, this integration is driven by the fundamental principle of creating a single, cohesive source of truth that breaks down silos and fosters end-to-end visibility.

This unified approach enables organizations to move beyond reactive problem-solving to proactive, data-driven decision-making, ultimately enhancing efficiency, reducing costs, and improving customer satisfaction. The ERP acts as the central nervous system of the supply chain, orchestrating activities across departments and partners, ensuring that every step in the process is synchronized and optimized. This seamless flow of information is critical for navigating the inherent volatility and complexities of modern supply chains, from sourcing raw materials to delivering finished products to the end consumer.The overarching goal of ERP integration in supply chain management is to achieve greater agility, resilience, and profitability.

This is accomplished by leveraging technology to automate processes, streamline workflows, and provide real-time insights into every facet of the supply chain. The principles guiding this integration emphasize standardization, data integrity, and interdepartmental collaboration. By establishing standardized processes and ensuring the accuracy and accessibility of data, ERP systems empower businesses to identify bottlenecks, anticipate disruptions, and make informed adjustments. This transforms the supply chain from a series of independent functions into a dynamic, interconnected ecosystem where information flows freely, enabling swift responses to market changes and customer demands.

The strategic alignment of ERP capabilities with supply chain objectives allows for a more predictive and optimized operational model, moving towards a truly integrated and intelligent supply chain.

Core Functionalities of an ERP System for Supply Chain Visibility and Control

An ERP system’s core functionalities are instrumental in providing unparalleled visibility and control over supply chain operations. These functionalities work in concert to transform raw data into actionable intelligence, allowing businesses to monitor, manage, and optimize every stage of the supply chain. From the initial procurement of raw materials to the final delivery of goods, the ERP system provides a centralized platform that tracks inventory levels, monitors production schedules, manages supplier relationships, and forecasts demand with greater accuracy.

This comprehensive oversight enables managers to identify potential issues before they escalate, such as stockouts, production delays, or transportation inefficiencies. For instance, real-time inventory tracking prevents overstocking, which ties up capital, and understocking, which leads to lost sales. Similarly, by monitoring production output against demand forecasts, businesses can adjust their manufacturing schedules to meet market needs efficiently.The visibility provided by an ERP extends beyond internal operations to encompass the entire network of suppliers and customers.

By integrating with supplier systems, businesses can gain insights into their production capacities, lead times, and potential risks. This proactive approach to supplier management helps in mitigating disruptions and ensuring a steady flow of materials. On the customer side, ERP systems can track order status, manage delivery schedules, and provide accurate delivery estimates, thereby enhancing customer satisfaction and loyalty. Furthermore, the financial modules within an ERP are tightly linked to supply chain activities, providing a clear picture of costs associated with procurement, production, inventory holding, and logistics.

This financial transparency is crucial for cost control and profitability analysis. Ultimately, these functionalities empower businesses with the ability to make informed decisions, optimize resource allocation, and respond swiftly to dynamic market conditions, thereby gaining a significant competitive advantage.

Consolidation of Disparate Supply Chain Data into a Unified Platform

One of the most significant contributions of an ERP system to supply chain management is its ability to consolidate vast amounts of disparate data into a single, coherent, and accessible platform. Historically, supply chain data was often scattered across various departmental spreadsheets, legacy systems, and individual databases, leading to inconsistencies, inaccuracies, and a lack of a holistic view. An ERP system breaks down these data silos by creating a centralized repository where all relevant information is stored, standardized, and made available to authorized users in real-time.

This unification process begins with data standardization, where common data formats and definitions are established across all supply chain functions. For example, product codes, customer identifiers, and supplier information are consistently managed, eliminating ambiguity and ensuring that everyone is working with the same set of facts.This consolidation is crucial for achieving end-to-end visibility. When data from procurement, inventory, production, sales, and logistics are integrated into one system, it becomes possible to trace the journey of a product from its raw materials to the customer.

This allows for detailed analysis of each stage, identifying areas of inefficiency or potential risk. For instance, by linking sales orders with inventory levels and production schedules, an ERP can automatically trigger replenishment orders or adjust production plans, ensuring that the right products are available at the right time and place. The platform also facilitates better collaboration by providing a shared view of information.

Different departments can access the same data, fostering better communication and coordination. For example, the sales team can see real-time inventory availability, preventing them from making promises they cannot keep, while the procurement team can access sales forecasts to plan material purchases more effectively.

The true power of an ERP lies in its ability to transform isolated data points into a connected, intelligent network, enabling strategic decision-making based on comprehensive, up-to-the-minute insights.

This unified data platform is not static; it is dynamic and continuously updated, reflecting the real-time status of the supply chain. This allows for immediate adjustments to be made in response to unforeseen events, such as a supplier delay or a sudden surge in demand. The ability to access a single version of the truth significantly reduces errors, improves decision-making speed, and enhances overall operational efficiency.

Essential ERP Modules for Effective Supply Chain Management

An ERP system comprises various interconnected modules, each contributing to the effective management of different aspects of the supply chain. For supply chain management specifically, several modules are considered critical for achieving optimal performance and control. These modules work in synergy to ensure that the flow of goods and information is seamless from end to end.

- Procurement Module: This module is the starting point for many supply chains, managing all activities related to acquiring goods and services. It handles vendor selection, purchase order creation, negotiation, and receiving of materials. Key functionalities include tracking supplier performance, managing contracts, and automating the purchasing process to ensure timely and cost-effective sourcing of raw materials and components. It also helps in managing supplier relationships and mitigating supply risks by providing visibility into supplier capabilities and potential disruptions.

- Inventory Management Module: Crucial for maintaining optimal stock levels, this module tracks the quantity, location, and movement of inventory across warehouses and distribution centers. It supports various inventory valuation methods, demand forecasting, safety stock calculations, and cycle counting. Effective inventory management, powered by this module, prevents stockouts, reduces carrying costs, and minimizes obsolescence, thereby optimizing working capital and ensuring product availability.

- Warehouse Management Module: This module focuses on the operational efficiency within warehouses. It manages inbound and outbound logistics, including receiving, put-away, picking, packing, and shipping. Advanced functionalities can include optimizing warehouse layout, managing labor, and tracking the movement of goods within the warehouse using technologies like barcoding and RFID. This leads to faster order fulfillment, reduced errors, and improved space utilization.

- Logistics and Transportation Management Module: This module oversees the movement of goods from origin to destination. It involves planning, executing, and optimizing transportation routes, carriers, and freight costs. Key features include load planning, shipment tracking, carrier performance evaluation, and freight auditing. By leveraging this module, businesses can reduce transportation expenses, improve delivery times, and enhance the overall efficiency of their distribution network.

- Manufacturing and Production Planning Module: For businesses involved in manufacturing, this module is vital for planning and controlling production processes. It includes capabilities for material requirements planning (MRP), capacity planning, shop floor control, and quality management. It ensures that production schedules align with demand, raw materials are available, and finished goods are produced to meet quality standards and delivery deadlines.

The interconnectedness of these modules ensures that data flows seamlessly between them. For instance, a sales order entered into the sales module can automatically trigger an inventory check, a production order if needed, and then initiate the logistics and shipping process once the goods are ready. This integrated approach eliminates manual data entry and reduces the likelihood of errors, leading to a more efficient and responsive supply chain.

Strategic Advantages of Aligning ERP Capabilities with Supply Chain Objectives

Aligning the capabilities of an ERP system with overarching supply chain objectives yields significant strategic advantages, transforming a company’s operational performance and competitive positioning. This alignment ensures that technology investments directly support the business’s goals for efficiency, cost reduction, customer satisfaction, and market responsiveness. One of the primary advantages is enhanced operational efficiency. By automating routine tasks, standardizing processes, and providing real-time data, ERP systems enable supply chains to operate with greater speed and accuracy.

This reduces lead times, minimizes errors, and optimizes resource utilization, directly contributing to lower operational costs. For example, a well-aligned ERP can automate purchase order generation based on real-time inventory levels and sales forecasts, preventing both overstocking and stockouts, thus optimizing inventory holding costs and ensuring product availability.Another critical strategic advantage is improved decision-making. The consolidated data and analytical tools provided by an ERP system offer unprecedented insights into supply chain performance.

This allows management to identify trends, anticipate potential disruptions, and make data-driven decisions rather than relying on intuition. For instance, by analyzing historical data on supplier lead times and delivery reliability, businesses can proactively identify at-risk suppliers and develop contingency plans, thereby building a more resilient supply chain. This predictive capability is invaluable in navigating the complexities and volatilities of global supply chains.

Strategic alignment transforms the supply chain from a cost center into a strategic differentiator, driving profitability and customer loyalty.

Furthermore, aligning ERP capabilities with supply chain objectives leads to enhanced customer satisfaction. With real-time visibility into inventory, production, and logistics, businesses can provide accurate order status updates, reliable delivery estimates, and faster fulfillment. This improved responsiveness and transparency build trust and loyalty with customers. For example, a customer can track their order from shipment to delivery, receiving proactive notifications about any potential delays, which significantly enhances their experience.

Moreover, this alignment fosters greater collaboration and integration across the entire supply chain network, including suppliers and partners. By sharing relevant data and insights through the ERP platform, businesses can build stronger relationships, improve coordination, and jointly address challenges, leading to a more cohesive and effective supply chain ecosystem. This integrated approach not only streamlines operations but also creates a competitive advantage by enabling quicker adaptation to market changes and customer demands.

Uncover the transformative effects of an ERP system on enhancing real-time decision-making throughout the supply chain.

An Enterprise Resource Planning (ERP) system acts as the central nervous system for a modern supply chain, fundamentally altering how businesses operate by providing unparalleled visibility and control. This transformation is not merely about digitizing processes; it’s about empowering organizations with the agility and intelligence needed to thrive in a dynamic global marketplace. By consolidating disparate data streams into a single, unified platform, ERP systems dismantle information silos, offering a holistic view of operations from raw material procurement to final product delivery.

This real-time accessibility is the bedrock upon which informed and swift decision-making is built, allowing companies to navigate complexities and capitalize on opportunities with unprecedented efficiency.

Mechanisms for Immediate Access to Crucial Supply Chain Metrics and Performance Indicators

The core strength of an ERP system in enhancing real-time decision-making lies in its ability to provide immediate access to a wealth of critical data. This is achieved through several interconnected mechanisms that ensure information is not only captured but also readily available and digestible for stakeholders across the supply chain. At the forefront is the centralized database, which serves as a single source of truth for all supply chain-related information.

Every transaction, from a purchase order being placed to a shipment being dispatched, is logged and updated in real-time within this repository. This eliminates the delays and inaccuracies associated with manual data entry or the integration of multiple, disconnected systems.Dashboards and reporting tools are key components that translate raw data into actionable insights. These customizable interfaces present key performance indicators (KPIs) and metrics in a visually intuitive format, allowing managers to quickly grasp the current state of operations.

For instance, a logistics manager can view real-time inventory levels across all warehouses, track the status of ongoing shipments, and monitor carrier performance against agreed-upon service levels, all from a single screen. Similarly, a procurement officer can access up-to-the-minute supplier lead times, material costs, and potential supply risks. The ability to drill down into specific data points provides the necessary detail for in-depth analysis, enabling immediate identification of bottlenecks, deviations from planned performance, or emerging issues.Furthermore, automated alerts and notifications are triggered when predefined thresholds or critical events occur.

This proactive notification system ensures that relevant personnel are immediately informed of significant changes, such as a sudden drop in inventory for a high-demand product, a delay in a critical shipment, or an unexpected spike in raw material prices. Instead of waiting for scheduled reports, decision-makers are alerted the moment an issue arises, allowing for rapid intervention. For example, if inventory for a key component falls below a reorder point, an automated alert can be sent to the purchasing department, along with suggested reorder quantities based on current demand forecasts and lead times.

This immediate awareness fosters a culture of proactive problem-solving, significantly reducing the impact of disruptions and optimizing operational responsiveness. The integration of IoT devices and sensors also plays a role, feeding real-time data on asset location, condition, and environmental factors directly into the ERP, further enriching the data available for immediate decision-making.

Predictive Analytics for Preempting Disruptions and Optimizing Resource Allocation

The true power of an ERP system extends beyond providing real-time data; it enables predictive analytics, transforming raw information into foresight. By leveraging the vast datasets collected and organized within the ERP, sophisticated algorithms can analyze historical trends, identify patterns, and forecast future outcomes. This capability is crucial for preempting potential disruptions before they impact the supply chain and for optimizing the allocation of resources to meet anticipated needs.

Predictive models can analyze sales data, market trends, economic indicators, and even external factors like weather patterns or geopolitical events to forecast demand with greater accuracy. This allows businesses to adjust production schedules, procurement plans, and inventory levels proactively, thereby mitigating the risk of stockouts or excess inventory.Consider a scenario where an ERP system, integrated with predictive analytics, identifies an increasing likelihood of a supplier experiencing production delays due to labor disputes in their region.

The system can flag this risk, prompting the procurement team to explore alternative suppliers, secure additional buffer stock, or even adjust production plans to prioritize products less reliant on that specific supplier. This proactive approach, informed by data-driven predictions, is far more effective and cost-efficient than reacting to a disruption after it has already occurred. Similarly, predictive maintenance modules, fed by sensor data from manufacturing equipment and logistics assets, can forecast potential equipment failures.

By scheduling maintenance before a breakdown occurs, companies can avoid costly downtime, production halts, and missed delivery deadlines.Resource allocation is another area profoundly impacted by predictive analytics. By forecasting demand and potential supply constraints, ERP systems can help optimize the deployment of capital, labor, and physical assets. For instance, if demand for a particular product is predicted to surge in the coming quarter, the ERP can help allocate production capacity, schedule overtime for manufacturing staff, and ensure sufficient raw materials are ordered in advance.

It can also optimize transportation routes and modes by predicting traffic patterns, fuel costs, and delivery times, ensuring that resources are used most efficiently. This data-driven approach to resource management minimizes waste, reduces operational costs, and enhances overall supply chain resilience. Real-world examples include companies using ERP-powered analytics to predict seasonal demand spikes for consumer goods, allowing them to pre-position inventory closer to key markets and optimize their distribution networks, thereby reducing delivery times and improving customer satisfaction.

Fostering Proactive Rather Than Reactive Responses to Fluctuating Market Demands and Supply Chain Challenges, Erp system for supply chain management

The shift from a reactive to a proactive operational stance is one of the most significant transformations an ERP system brings to supply chain management. Historically, many businesses operated in a reactive mode, addressing issues as they arose. This often led to costly fire-fighting, missed opportunities, and strained relationships with suppliers and customers. An ERP system, by providing comprehensive visibility and advanced analytical capabilities, empowers organizations to anticipate challenges and opportunities, enabling them to act proactively.

This proactive mindset permeates all levels of the supply chain, from strategic planning to day-to-day execution.When market demands fluctuate, an ERP system provides the intelligence needed to adapt swiftly. For instance, if consumer preferences shift rapidly towards a new product or feature, the ERP can quickly analyze sales data, identify the trend, and inform production and procurement teams. Instead of scrambling to retool or source new materials, a proactive organization, guided by ERP insights, will have already identified potential suppliers for new components, adjusted production forecasts, and potentially even initiated preliminary design changes.

This allows them to capture market share quickly and efficiently. Conversely, if demand for a product unexpectedly declines, the ERP can signal this change early, allowing for adjustments to production schedules, inventory reduction strategies, and marketing efforts to mitigate losses.Supply chain challenges, such as unexpected port congestion, natural disasters affecting a key supplier, or geopolitical instability impacting trade routes, are also better managed proactively.

An ERP system, by mapping out the entire supply chain network and identifying critical nodes and dependencies, can simulate the impact of various disruptions. This allows businesses to develop contingency plans, identify alternative suppliers or transportation routes, and build resilience into their operations. For example, a company might use its ERP to identify that a significant portion of its critical components comes from a single region prone to seismic activity.

Proactive measures could include diversifying its supplier base, holding strategic safety stock, or investing in supply chain risk management software integrated with the ERP. The ability to run “what-if” scenarios within the ERP environment allows for the testing and refinement of these proactive strategies before they are needed. This forward-thinking approach not only minimizes the impact of disruptions but also enhances the company’s reputation for reliability and customer service.

Conceptual Framework Illustrating the Flow of Information for Swift and Informed Operational Adjustments

The conceptual framework for information flow within an ERP system that enables swift and informed operational adjustments can be visualized as a continuous, cyclical process driven by data integration and intelligent analysis. At its core is the Centralized Data Repository, where all supply chain activities are recorded in real-time. This includes data from various modules such as procurement, inventory management, manufacturing, sales, and logistics.

This repository acts as the single source of truth, ensuring consistency and accuracy across all operational areas.The next crucial element is the Data Integration Layer. This layer is responsible for capturing data from all touchpoints within the supply chain, whether it’s from shop floor machinery, warehouse scanners, customer orders, or supplier invoices. This data is then standardized and fed into the central repository.

Real-time data feeds are paramount here; for example, a sales order confirmation immediately updates inventory levels and triggers a replenishment request if necessary.Following data integration, the Analytics and Intelligence Engine comes into play. This engine utilizes the consolidated data to generate insights. It encompasses several sub-components:

- Real-time Monitoring & Dashboards: Visual representations of key metrics and KPIs, allowing immediate visibility into operational status. This could include live inventory counts, order fulfillment rates, and on-time delivery percentages.

- Reporting Tools: Generation of detailed reports for deeper analysis, trend identification, and performance evaluation.

- Predictive Analytics Module: Employing algorithms to forecast future demand, identify potential risks (e.g., supplier delays, equipment failures), and optimize resource needs.

- Scenario Planning & Simulation: Tools that allow users to model the impact of different decisions or external events on the supply chain.

The output of this engine is then disseminated through the Decision Support and Action Layer. This layer translates insights into actionable recommendations and triggers automated workflows. For instance, if predictive analytics forecast a surge in demand for a product, this layer might automatically generate a revised production schedule and a purchase order for necessary raw materials. Alerts and notifications are also managed here, pushing critical information to the relevant stakeholders.Finally, the Operational Execution and Feedback Loop closes the cycle.

Based on the decisions and actions taken, operational adjustments are implemented. These adjustments, in turn, generate new data that feeds back into the Centralized Data Repository, initiating the next cycle. For example, if a production adjustment is made based on a forecast, the actual production output and material consumption are recorded, refining future forecasts and analyses.This continuous flow ensures that information is not static but dynamic, enabling rapid adaptation.

A simple illustration: a customer places a large, unexpected order (data input). The ERP immediately updates sales figures and checks inventory. If inventory is insufficient, it triggers a replenishment alert based on current stock levels and lead times (analytics and intelligence). The system might then suggest expediting a shipment from a supplier or rerouting existing stock (decision support). The logistics team acts on this, adjusting shipping plans (operational execution), and the updated shipment status is fed back into the system (feedback loop), allowing for real-time tracking and customer updates.

This seamless loop empowers swift and informed adjustments to maintain operational efficiency and customer satisfaction.

Explore the practical implementation strategies for deploying an enterprise resource planning solution to streamline supply chain processes.

Implementing an Enterprise Resource Planning (ERP) system within a supply chain is a significant undertaking that requires careful planning and execution. It’s not simply about installing software; it’s about transforming how an organization manages its entire flow of goods, information, and finances. This section delves into the practical steps involved in making this transformation a reality, from initial selection to ongoing integration and operationalization.The successful deployment of an ERP system hinges on a methodical approach that addresses every facet of the supply chain.

This includes not only the technology itself but also the people, processes, and data that are intrinsically linked. By breaking down the implementation into manageable phases and adhering to established best practices, organizations can significantly increase their chances of achieving the desired operational efficiencies and strategic advantages.

Selecting an ERP System Tailored to Specific Supply Chain Needs

Choosing the right ERP system is a foundational step that dictates the ultimate success of your supply chain transformation. This process demands a thorough understanding of your unique operational challenges, strategic goals, and the specific functionalities required to address them. A haphazard selection can lead to costly rework, underutilization of features, and ultimately, a failure to achieve the desired return on investment.

Therefore, a structured and comprehensive evaluation process is paramount.The selection journey typically begins with a detailed needs assessment. This involves engaging key stakeholders from across the supply chain – procurement, logistics, manufacturing, warehousing, sales, and finance – to identify pain points, bottlenecks, and areas for improvement. Documenting these requirements forms the basis for creating a Request for Proposal (RFP) that clearly articulates the functional and technical specifications.

Following the RFP, a critical phase is vendor evaluation. This involves shortlisting potential ERP providers based on their industry experience, the robustness of their supply chain modules, their financial stability, and their reputation for customer support and implementation success. Demonstrations and pilot programs are invaluable here, allowing your team to see the system in action and assess its usability and fit with your existing workflows.

Beyond the core software features, consider the total cost of ownership, including licensing, implementation, customization, training, and ongoing maintenance. System configuration is another crucial element. This is where the chosen ERP system is adapted to mirror your specific business processes. This might involve setting up workflows, defining master data structures, configuring user roles and permissions, and tailoring reports and dashboards to provide actionable insights.

Over-configuration can lead to complexity and increased costs, while under-configuration can result in a system that doesn’t fully meet your needs. A balanced approach, focusing on essential customizations that deliver significant value, is key.

- Define Clear Business Objectives: Before even looking at vendors, establish what you aim to achieve with the ERP system. Is it reducing inventory costs, improving on-time delivery rates, enhancing forecast accuracy, or gaining better visibility across the entire supply chain?

- Map Existing Supply Chain Processes: Thoroughly document current workflows, identifying inefficiencies, redundancies, and areas where technology can provide a significant uplift. This forms the baseline for evaluating how an ERP can improve operations.

- Prioritize Essential Functionalities: Categorize required features into ‘must-have,’ ‘should-have,’ and ‘nice-to-have’ to guide your selection and avoid feature bloat. For supply chain management, this typically includes modules for inventory management, procurement, warehouse management, transportation management, demand planning, and order fulfillment.

- Conduct Thorough Vendor Due Diligence: Research potential vendors, focusing on their track record in your industry, the scalability of their solutions, their commitment to innovation, and the quality of their customer support and implementation services. Request case studies and speak with existing clients.

- Evaluate System Architecture and Technology Stack: Ensure the ERP system’s underlying technology is modern, secure, and compatible with your existing IT infrastructure. Consider aspects like integration capabilities, data security protocols, and the ease of future upgrades.

- Assess Implementation Methodology and Support: Understand the vendor’s proposed implementation plan, including timelines, resource requirements, and their approach to change management and user training. Evaluate the level of ongoing support they offer post-implementation.

- Calculate Total Cost of Ownership (TCO): Go beyond initial licensing fees to include costs for implementation, customization, data migration, training, hardware (if applicable), ongoing maintenance, and potential future upgrades.

- Request Detailed Demonstrations and Proof of Concepts: Insist on seeing how the system handles your specific use cases. A proof of concept (POC) can be invaluable for testing critical functionalities with your own data in a simulated environment.

- Negotiate Contracts Carefully: Pay close attention to service level agreements (SLAs), licensing terms, data ownership clauses, and exit strategies.

A Phased Approach to ERP Implementation

Implementing an ERP system is a complex endeavor that is best managed through a structured, phased approach. This strategy breaks down the massive undertaking into smaller, more manageable stages, allowing for iterative progress, risk mitigation, and continuous learning. A big-bang, all-at-once implementation, while potentially faster in theory, carries a much higher risk of disruption and failure. A phased rollout allows the organization to adapt gradually, refine processes, and build confidence with each successful stage.The initial phase typically focuses on foundational elements and critical business functions.

This often includes the successful migration of master data – the core information about products, customers, vendors, and suppliers – which is the lifeblood of any ERP system. Inaccurate or incomplete data can cripple the system from the outset. Therefore, data cleansing, validation, and transformation are paramount. This phase also usually involves configuring and testing core modules, such as financials and procurement, to ensure they are operational and aligned with business requirements.

Following this, a significant emphasis is placed on user training. Comprehensive training programs are essential to equip employees with the skills and knowledge needed to effectively use the new system. This training should be tailored to different user roles and responsibilities, utilizing a variety of methods like classroom sessions, e-learning modules, and hands-on practice. Change management is an overarching concern throughout all phases.

It involves proactively addressing the human element of the implementation, communicating the benefits of the ERP, managing resistance to change, and fostering a culture of adoption. Subsequent phases then build upon this foundation, progressively rolling out more complex modules like inventory management, warehouse management, and advanced planning and scheduling. Each phase should include rigorous testing, user acceptance testing (UAT), and a review of lessons learned before proceeding to the next.

- Phase 1: Planning and Design

- Form a dedicated project team with representatives from all key departments.

- Define detailed project scope, objectives, and success metrics.

- Conduct a thorough gap analysis between business requirements and ERP capabilities.

- Develop a comprehensive project plan, including timelines, resource allocation, and budget.

- Establish a robust change management strategy and communication plan.

- Select the ERP vendor and implementation partner.

- Define data migration strategy and initiate data cleansing efforts.

- Phase 2: Core System Configuration and Data Migration

- Configure foundational modules such as Finance, Procurement, and Human Resources.

- Perform initial data migration of cleansed master data (e.g., chart of accounts, vendor masters, customer masters).

- Conduct unit testing and initial integration testing for core modules.

- Develop user training materials for core functionalities.

- Begin initial user awareness and buy-in activities.

- Phase 3: Rollout of Key Supply Chain Modules

- Configure and test critical supply chain modules like Inventory Management, Order Management, and Warehouse Management.

- Migrate relevant transactional and historical data for these modules.

- Conduct comprehensive user training for personnel operating these modules.

- Perform User Acceptance Testing (UAT) with end-users to validate functionality.

- Execute a pilot rollout or phased go-live for these modules in a controlled environment.

- Gather feedback and make necessary adjustments.

- Phase 4: Advanced Functionality and Optimization

- Implement advanced modules such as Demand Planning, Transportation Management, and Production Planning.

- Integrate with external systems and partner platforms.

- Conduct further data migration for specialized areas.

- Provide advanced training and ongoing support.

- Focus on performance optimization and continuous improvement initiatives.

- Measure against defined success metrics and identify further opportunities for enhancement.

Best Practices for Integrating an ERP with Existing Supply Chain Technologies and Partner Systems

Seamless integration is the linchpin of a truly effective ERP system in supply chain management. An ERP doesn’t operate in a vacuum; it needs to communicate and exchange data with a multitude of other systems, both internal and external. Failure to achieve robust integration can lead to data silos, manual workarounds, and a significant reduction in the efficiency gains that an ERP promises.

Therefore, a strategic and disciplined approach to integration is essential for unlocking the full potential of your ERP investment.The process begins with a clear understanding of your existing technology landscape. This involves mapping out all the systems that interact with or are affected by the ERP, including Warehouse Management Systems (WMS), Transportation Management Systems (TMS), Customer Relationship Management (CRM) software, e-commerce platforms, manufacturing execution systems (MES), and any specialized supply chain planning tools.

For each system, identify the data flows, the frequency of data exchange, and the criticality of that data. Once this landscape is understood, the next step is to define an integration strategy. This often involves leveraging Application Programming Interfaces (APIs), which are standardized protocols that allow different software applications to communicate with each other. Modern ERP systems are typically built with robust API capabilities, facilitating easier integration.

For older or legacy systems that may not have readily available APIs, middleware solutions or custom connectors might be necessary. Another critical aspect is data standardization. Ensuring that data is formatted consistently across all integrated systems is vital to prevent errors and misinterpretations. This might involve establishing common data dictionaries and transformation rules. Furthermore, building strong relationships with your supply chain partners and ensuring their systems can also integrate with yours is crucial.

This often involves collaborative discussions about data exchange formats and protocols. Finally, ongoing monitoring and maintenance of integrations are essential. Systems evolve, and integrations need to be updated to ensure continued functionality and security.

- Conduct a Comprehensive Inventory of Existing Systems: Map out all current software applications, databases, and hardware that interact with or are part of the supply chain. This includes WMS, TMS, CRM, MES, e-commerce platforms, and any third-party logistics (3PL) provider systems.

- Define Clear Data Exchange Requirements: For each integration point, specify what data needs to be exchanged, the direction of the flow (e.g., ERP to WMS, WMS to ERP), the frequency of updates (e.g., real-time, batch), and the acceptable data formats.

- Prioritize Integration Points Based on Business Impact: Focus on integrating the systems that have the most significant impact on core supply chain processes and offer the greatest potential for efficiency gains and cost savings.

- Leverage Standard APIs and Connectors: Whenever possible, utilize the pre-built APIs and connectors offered by your ERP vendor and other software providers. This significantly reduces development time and complexity.

- Implement a Robust Middleware Strategy: For complex integration scenarios or when dealing with legacy systems lacking APIs, consider using middleware platforms. These act as an intermediary, facilitating communication and data transformation between disparate systems.

- Establish Data Standardization and Governance: Define master data standards and implement data cleansing and validation processes to ensure data consistency and accuracy across all integrated systems. This is critical for preventing errors and enabling reliable reporting.

- Develop a Scalable and Secure Integration Architecture: Design an integration framework that can accommodate future growth and evolving business needs. Ensure all integrations adhere to stringent security protocols to protect sensitive supply chain data.

- Collaborate Closely with Supply Chain Partners: Engage your key suppliers, customers, and logistics providers in discussions about integration. Understand their technical capabilities and work collaboratively to establish mutually beneficial data exchange mechanisms.

- Implement Comprehensive Testing and Monitoring: Rigorously test all integrations before and after go-live. Establish ongoing monitoring mechanisms to detect and resolve integration issues promptly, ensuring uninterrupted data flow.

- Plan for Ongoing Maintenance and Updates: Recognize that integrations are not a one-time setup. Regularly review and update integrations to accommodate software upgrades, changes in business processes, or new partner requirements.

Comparative Analysis of ERP Deployment Models for Supply Chain Operations

The choice of deployment model for an ERP system significantly impacts its cost, scalability, security, and the speed at which it can be implemented and adapted within a supply chain context. Organizations must carefully consider their unique operational needs, IT infrastructure capabilities, budget constraints, and strategic priorities when deciding between on-premise, cloud-based, or hybrid solutions. Each model offers distinct advantages and disadvantages that directly affect supply chain efficiency and agility.On-premise ERP systems are installed and managed entirely within an organization’s own data centers.

This offers the highest level of control over data security and customization. For supply chains that handle highly sensitive proprietary information or operate in heavily regulated industries, this control can be a critical factor. However, on-premise solutions typically involve a substantial upfront investment in hardware, software licenses, and IT personnel for maintenance and support. The implementation timeline can also be longer due to the need for physical infrastructure setup and configuration.

Cloud-based ERP systems, often delivered as Software-as-a-Service (SaaS), are hosted by a third-party vendor and accessed over the internet. This model offers significant advantages in terms of rapid deployment, scalability, and reduced upfront costs, as it shifts expenses from capital expenditure to operational expenditure. For dynamic supply chains that require quick adaptation to changing market demands or seasonal peaks, the elasticity of cloud solutions is a major benefit.

Vendors handle maintenance, updates, and security, freeing up internal IT resources. However, organizations have less direct control over the underlying infrastructure and data, which can be a concern for some. Hybrid ERP models combine elements of both on-premise and cloud solutions. This approach allows organizations to keep sensitive data or critical legacy systems on-premise while leveraging the cloud for other functionalities, such as CRM or demand forecasting.

This offers a balanced approach, providing flexibility and control. For example, a company might host its core manufacturing and inventory management modules on-premise for maximum control, while using a cloud-based TMS for its transportation network, benefiting from the vendor’s specialized expertise and real-time tracking capabilities. This hybrid approach can be particularly effective for complex supply chains with diverse needs.

| Deployment Model | Description | Advantages for Supply Chain | Disadvantages for Supply Chain | Ideal Use Cases |

|---|---|---|---|---|

| On-Premise | Software is installed and managed on the organization’s own servers and infrastructure. |

|

|

|

| Cloud-Based (SaaS) | Software is hosted by a third-party vendor and accessed via the internet, typically on a subscription basis. |

|

|

|

| Hybrid | A combination of on-premise and cloud-based solutions, where some functionalities reside on-premise and others in the cloud. |

|

|

|

Illustrate the tangible benefits an enterprise resource planning system brings to operational efficiency and cost reduction in supply chain management.

An enterprise resource planning (ERP) system is a powerful catalyst for transforming supply chain operations, directly impacting operational efficiency and driving significant cost reductions. By integrating disparate functions and providing a single source of truth, ERP solutions empower businesses to make smarter, data-driven decisions across the entire supply chain, from procurement to delivery. This leads to a more agile, responsive, and ultimately, more profitable operation.The true value of an ERP system in supply chain management lies in its ability to provide end-to-end visibility and control.

This holistic view allows for the identification and elimination of inefficiencies that often plague traditional, siloed systems. The subsequent optimization of processes, reduction of waste, and improvement in resource utilization translate directly into tangible financial benefits and a stronger competitive advantage.

Inventory Optimization and Cost Reduction

Optimizing inventory levels is a cornerstone of efficient supply chain management, and ERP systems excel in this area by providing real-time data and sophisticated analytical tools. Instead of relying on manual counts or outdated spreadsheets, an ERP system offers an accurate, up-to-the-minute view of stock on hand across all locations. This visibility is crucial for preventing both overstocking, which ties up capital and incurs holding costs, and understocking, which leads to lost sales and customer dissatisfaction.Specific examples of how ERP systems optimize inventory levels include:

- Automated Reorder Points: ERP systems can be configured with dynamic reorder points based on historical sales data, lead times, and desired service levels. When inventory for a specific item falls below this threshold, the system automatically generates a purchase requisition or production order, ensuring timely replenishment. For instance, a retail company using an ERP might set a reorder point for a popular seasonal item.

As sales increase and stock depletes, the system triggers an alert and initiates an order with the supplier well in advance of a potential stockout.

- Demand-Driven Planning: Advanced ERP modules incorporate demand forecasting capabilities. By analyzing historical sales patterns, market trends, and even external factors like weather or promotional activities, the ERP can predict future demand with greater accuracy. This allows businesses to align inventory levels with anticipated needs, minimizing excess stock. A manufacturing firm might use its ERP to forecast demand for a particular component based on upcoming product launches and historical performance, adjusting raw material orders accordingly to avoid holding unnecessary raw materials.

- Warehouse Slotting and Optimization: ERP systems can track inventory by location within a warehouse, facilitating efficient slotting. By placing fast-moving items in easily accessible locations and slower-moving items in less accessible areas, picking times are reduced, and labor costs are lowered. This also aids in managing expiry dates for perishable goods, ensuring older stock is used first (FIFO – First-In, First-Out), thereby minimizing spoilage and associated write-offs.

- Reduced Carrying Costs: By maintaining optimal inventory levels, businesses significantly reduce carrying costs, which include expenses like warehousing, insurance, taxes, obsolescence, and damage. For example, a consumer goods distributor that previously held 30 days of safety stock for all its products might, with ERP-driven insights, reduce this to 15 days for high-turnover items, freeing up substantial capital and reducing storage space requirements.

- Minimized Stockouts: The proactive nature of ERP-driven inventory management drastically reduces stockouts. When a stockout does occur, the ERP can immediately identify alternative sources or suggest substitute products, mitigating the impact on sales and customer relationships. A pharmaceutical company, for instance, can use its ERP to monitor critical drug inventory and automatically source from alternative suppliers if the primary supplier faces production issues, preventing life-threatening shortages.

Improved Order Fulfillment Accuracy and Lead Times

The impact of an ERP system on improving order fulfillment accuracy and lead times is profound, directly contributing to enhanced customer satisfaction. By centralizing and streamlining all order-related processes, ERP solutions eliminate manual errors, reduce processing times, and provide real-time visibility into order status, creating a more reliable and efficient customer experience.The following illustrate the impact:

- End-to-End Order Visibility: From the moment an order is placed, an ERP system tracks its journey through every stage: order entry, credit checking, inventory allocation, picking, packing, shipping, and invoicing. This comprehensive visibility allows customer service representatives to provide accurate and timely updates to customers, fostering trust and reducing inquiries. A B2B client can log into a customer portal integrated with the ERP and see the exact status of their order, including when it was picked, packed, and shipped, and even access tracking information.

- Reduced Order Processing Time: Automation is key. ERP systems automate many of the manual tasks involved in order processing, such as data entry, price verification, and inventory checks. This significantly reduces the time it takes to get an order from submission to fulfillment. For example, an e-commerce business can process hundreds of orders per hour with an ERP, compared to manual processing which might only handle a few dozen, leading to faster dispatch and delivery.

- Increased Order Accuracy: Manual data entry is prone to errors, leading to incorrect items being shipped, wrong quantities, or incorrect addresses. An ERP system, through standardized data input and validation rules, minimizes these errors. Barcode scanning during picking and packing further enhances accuracy, ensuring that the correct items are dispatched to the correct customers. A large electronics retailer using an ERP with integrated warehouse management can drastically cut down on shipping errors, ensuring customers receive exactly what they ordered.

- Shorter Lead Times: By optimizing inventory, streamlining picking and packing, and improving communication between departments, ERP systems contribute to shorter overall lead times. This means customers receive their orders faster, which is a significant competitive differentiator in today’s fast-paced market. A furniture manufacturer can reduce its order-to-delivery lead time from four weeks to two weeks by using an ERP to better manage production schedules and material procurement.

- Enhanced Customer Satisfaction: The cumulative effect of accurate orders, faster delivery, and proactive communication leads to a significant boost in customer satisfaction. Happy customers are more likely to become repeat customers and recommend the business to others. A study by a software vendor showed that companies implementing ERP experienced a 15% increase in customer retention rates due to improved order fulfillment.

Identification and Elimination of Inefficiencies in Transportation and Logistics

An ERP system plays a crucial role in identifying and eliminating inefficiencies within transportation and logistics operations, leading to substantial reductions in freight expenses. By providing a unified platform for managing all aspects of goods movement, ERP enables better planning, execution, and analysis of logistics activities.Here’s a breakdown of how ERP achieves this:

- Route Optimization: ERP systems can integrate with transportation management modules (TMS) or offer built-in capabilities to optimize delivery routes. By considering factors such as delivery locations, vehicle capacity, traffic conditions, and delivery time windows, the system can generate the most efficient routes, minimizing mileage, fuel consumption, and driver hours. A food distribution company can use its ERP to plan daily delivery routes for its fleet, ensuring that drivers visit multiple customers in a single, optimized trip, thereby reducing the number of miles driven by 10-15% annually.

- Load Consolidation: The ability to view all pending shipments across different orders and customers allows ERP systems to facilitate load consolidation. By grouping smaller shipments destined for similar regions, businesses can utilize full truckloads, reducing the cost per unit shipped. For example, a chemical supplier can consolidate several small orders going to different clients within the same industrial park onto a single, larger truck, avoiding multiple smaller, less economical trips.

- Carrier Performance Management: ERP systems can track carrier performance metrics such as on-time delivery rates, damage claims, and freight costs. This data allows businesses to identify underperforming carriers and negotiate better rates with reliable ones. A large retailer can use its ERP to analyze the performance of its various shipping partners, identifying which carriers consistently meet delivery deadlines and offer competitive pricing, leading to better contract negotiations.

- Reduced Empty Miles: By providing visibility into inbound and outbound logistics, ERP systems can help minimize “empty miles” – the distance vehicles travel without carrying any cargo. This can be achieved through backhauling opportunities, where a truck returning from a delivery picks up a load from a supplier or another customer. A manufacturing company might use its ERP to coordinate inbound raw material deliveries with outbound finished goods shipments, ensuring its trucks are rarely running empty.

- Streamlined Documentation and Compliance: ERP systems automate the generation of shipping documents, bills of lading, and customs forms, reducing administrative burden and the risk of errors. This also ensures compliance with regulations, preventing costly delays and fines. For international shipments, accurate and complete documentation managed by the ERP is vital to avoid customs issues.

- Real-time Tracking and Visibility: Many ERP systems offer real-time tracking of shipments, allowing for proactive management of potential delays. If a shipment is running late, the system can trigger alerts, enabling the logistics team to inform the customer and make necessary adjustments. This visibility also helps in identifying bottlenecks in the transportation network.

Financial Advantages through Better Demand Forecasting and Procurement Planning

The financial advantages realized through better demand forecasting and procurement planning facilitated by an ERP system are substantial, impacting profitability and cash flow directly. By providing accurate insights into future needs and optimizing the purchasing process, ERP empowers businesses to make more strategic financial decisions.The financial benefits are realized in several key areas:

- Optimized Working Capital: Accurate demand forecasts, powered by ERP analytics, allow businesses to align procurement with actual sales projections. This means purchasing raw materials and finished goods only when they are needed, thereby reducing the amount of capital tied up in inventory. For instance, a fashion retailer using an ERP’s forecasting capabilities can avoid overstocking seasonal items that might quickly become obsolete, freeing up cash for other investments or operational needs.

- Reduced Procurement Costs: ERP systems facilitate better procurement planning by providing a consolidated view of all purchase requirements. This allows for bulk purchasing opportunities, negotiation of better prices with suppliers based on anticipated volumes, and the identification of cost-saving alternatives. A construction company can use its ERP to aggregate material needs for multiple projects, negotiate volume discounts with suppliers, and secure more favorable payment terms.

- Improved Budgeting and Financial Planning: With more reliable demand forecasts and a clearer understanding of procurement needs, businesses can create more accurate budgets and financial plans. This reduces the likelihood of unexpected shortfalls or surpluses, leading to more stable financial performance. A company can forecast its raw material expenditure for the next quarter with greater confidence, enabling more precise cash flow management.

- Minimized Expedited Shipping Costs: Proactive procurement planning, driven by ERP, significantly reduces the need for costly expedited shipping. When businesses are caught off guard by demand or supply issues, they often resort to premium shipping methods to meet deadlines. An ERP system, by anticipating needs, ensures that orders are placed and materials are received well in advance, eliminating the need for such expensive measures.

- Enhanced Supplier Relationship Management: ERP systems often include supplier management modules that track supplier performance, payment history, and contract terms. This data allows for more strategic engagement with suppliers, potentially leading to better pricing, extended payment terms, and improved service levels, all of which contribute to financial health. A manufacturing firm can leverage its ERP data to identify its most reliable and cost-effective suppliers and build stronger, mutually beneficial partnerships.

- Reduction in Write-offs and Obsolescence: By aligning procurement with accurate demand forecasts, ERP systems help minimize the risk of purchasing goods that will not be sold or that will become obsolete. This directly reduces write-offs and the financial impact of inventory obsolescence. A technology distributor can use its ERP to predict the lifecycle of electronic components and adjust its purchasing strategy accordingly, preventing the accumulation of outdated stock.

The Future Trajectory of Enterprise Resource Planning Systems in Shaping Supply Chain Management Evolution

The landscape of supply chain management is in a perpetual state of evolution, driven by an ever-increasing demand for speed, transparency, and adaptability. Enterprise Resource Planning (ERP) systems, once primarily viewed as backbone operational tools, are now at the forefront of this transformation, acting as intelligent orchestrators of complex global networks. The future trajectory of ERPs in supply chain management is not merely about incremental improvements; it’s about a fundamental paradigm shift towards predictive, autonomous, and highly responsive ecosystems.

As businesses grapple with unprecedented disruptions, from geopolitical shifts to climate change impacts, the role of ERPs in navigating these challenges and fostering a more robust supply chain will only intensify.

Integration of Emerging Technologies into ERP for Advanced Supply Chain Capabilities

The integration of cutting-edge technologies like Artificial Intelligence (AI) and Machine Learning (ML) into ERP systems is fundamentally redefining supply chain capabilities, moving them from reactive to proactive and even predictive modes. AI and ML algorithms can process vast datasets generated across the entire supply chain – from raw material sourcing to final customer delivery – identifying patterns, anomalies, and potential risks that human analysis might miss.

For instance, predictive analytics powered by ML can forecast demand with unprecedented accuracy, taking into account myriad factors such as historical sales, market trends, social media sentiment, and even weather patterns. This allows for optimized inventory management, reducing both stockouts and costly overstocking. Furthermore, AI-driven route optimization algorithms can dynamically adjust logistics plans in real-time, considering traffic conditions, fuel prices, and delivery windows, thereby minimizing transportation costs and lead times.

Machine learning is also instrumental in anomaly detection, flagging potential quality issues in manufacturing or deviations in supplier performance before they escalate into significant problems. Natural Language Processing (NLP), a subset of AI, is enhancing communication and data extraction, allowing ERP systems to interpret unstructured data from emails, reports, and customer feedback, providing actionable insights. Reinforcement learning models are being explored to autonomously manage warehouse operations, optimizing pick-and-pack processes and robotic movements.

The synergy between ERP and these advanced technologies creates a powerful engine for continuous improvement, enabling organizations to not only respond effectively to disruptions but also to anticipate and mitigate them, thereby building a more resilient and efficient supply chain.

Development of Agile and Resilient Supply Chains Driven by Intelligent ERP Solutions

Intelligent ERP solutions are pivotal in fostering the development of supply chains that are not only agile but also inherently resilient, capable of withstanding and rapidly recovering from disruptions. The core of this intelligence lies in the ERP’s ability to provide end-to-end visibility and a unified source of truth across all supply chain nodes. When an unexpected event occurs, such as a natural disaster impacting a key manufacturing hub or a sudden surge in demand for a particular product, an intelligent ERP can immediately identify the ripple effects across the entire network.

This allows for rapid scenario planning and the swift execution of contingency measures. For example, if a primary supplier is affected, the ERP can instantly assess alternative sourcing options based on pre-defined criteria like cost, lead time, and reliability, and even initiate automated re-ordering processes from secondary suppliers. AI-powered risk assessment modules within the ERP can continuously monitor global events, geopolitical stability, and supplier financial health, flagging potential threats long before they materialize.

This proactive approach enables businesses to build redundancy into their supply chains, perhaps by diversifying their supplier base or establishing strategic buffer stocks in key regions, all managed and optimized by the ERP. Furthermore, intelligent ERPs facilitate dynamic network reconfiguration. In a volatile market, the ability to quickly shift production, reroute shipments, or adjust distribution channels without significant manual intervention is crucial.

ML algorithms can analyze real-time performance data and recommend optimal adjustments to network flows, ensuring that the supply chain remains fluid and responsive to changing conditions. The resilience fostered by these systems is not just about bouncing back; it’s about adapting and thriving in the face of uncertainty, ensuring business continuity and customer satisfaction even in the most challenging environments.

ERP System Adaptation to Global Complexities and Evolving Consumer Expectations

The global supply chain is an intricate web of international regulations, diverse logistical challenges, and rapidly shifting consumer demands. ERP systems are continuously adapting to manage this growing complexity, becoming more sophisticated in their ability to integrate disparate systems and provide a holistic view of operations. As globalization deepens, ERPs are being designed with enhanced multi-currency, multi-language, and multi-regulatory compliance capabilities.

This is crucial for businesses operating across different continents, ensuring that all transactions and processes adhere to local laws and standards, from trade tariffs to environmental regulations. The rise of e-commerce and the “Amazon effect” have dramatically heightened consumer expectations for speed, personalization, and transparency. Consumers now expect real-time order tracking, flexible delivery options, and seamless returns, all of which place immense pressure on supply chain operations.

Modern ERP systems are responding by integrating with customer-facing platforms and leveraging advanced analytics to predict consumer behavior and optimize fulfillment strategies. For instance, ERPs can now power sophisticated demand sensing capabilities, allowing businesses to anticipate localized demand spikes and adjust inventory and distribution accordingly. They also facilitate micro-fulfillment strategies, enabling faster delivery from distributed inventory points. Furthermore, the demand for ethical and sustainable sourcing is becoming a significant factor.

Consumers are increasingly scrutinizing the origin of products and the ethical practices of companies. ERP systems are evolving to incorporate robust traceability features, allowing businesses to track products from raw material to end-user, verifying ethical sourcing, fair labor practices, and environmental impact at each stage. This transparency is not only a response to consumer pressure but also a strategic imperative for brand reputation and long-term viability in an increasingly conscious marketplace.

The ability of ERPs to ingest and analyze data from a multitude of sources, from IoT sensors on shipments to social media sentiment, is key to their adaptation in this complex and dynamic environment.

Vision for Advanced ERP Functionalities Supporting Sustainability and Ethical Sourcing

The future vision for advanced ERP functionalities is deeply intertwined with the imperative for sustainability and ethical sourcing within supply chain operations. ERP systems will evolve into powerful platforms that not only optimize efficiency and profitability but also actively drive positive environmental and social impact. Imagine an ERP system that automatically calculates the carbon footprint of every transportation route and suggests the most sustainable alternatives, factoring in fuel efficiency, vehicle type, and even potential for consolidated shipments.

This would involve integrating real-time emissions data and leveraging AI to identify optimal routes that minimize environmental impact. Furthermore, ERPs will become central to managing circular economy principles. They will track product lifecycles from inception, facilitating the efficient collection, refurbishment, and recycling of materials, thereby reducing waste and conserving resources. This requires sophisticated inventory management that can differentiate between new, refurbished, and recycled components, and optimize their reintegration into production.

On the ethical sourcing front, advanced ERPs will move beyond basic supplier compliance checks. They will incorporate blockchain technology to create immutable records of product provenance, ensuring that raw materials are sourced from conflict-free zones and that labor practices throughout the supply chain adhere to stringent ethical standards. This provides irrefutable proof of ethical conduct to consumers and regulatory bodies.

For example, a clothing manufacturer could use their ERP to trace the origin of cotton back to the farm, verifying fair wages for agricultural workers and the absence of child labor, with this information accessible to consumers via a QR code on the garment. AI will play a crucial role in risk assessment related to ethical sourcing, analyzing news feeds, NGO reports, and social media to flag potential human rights abuses or environmental violations within a supplier’s operations.

The ERP would then trigger alerts and initiate audits or alternative sourcing strategies. This proactive approach transforms sustainability and ethical sourcing from a compliance burden into a strategic advantage, enabling businesses to build trust, enhance brand loyalty, and contribute to a more responsible global economy, all orchestrated and managed through an intelligent, purpose-driven ERP system.

Conclusion

In essence, the ERP system for supply chain management is not merely a technological tool but a strategic imperative for businesses seeking to thrive in today’s dynamic global economy. Its ability to enhance real-time decision-making, streamline implementation, drive operational efficiency, and foster collaboration across the entire network positions it as indispensable. As we look to the future, the integration of advanced technologies like AI and machine learning within ERP promises even more agile, resilient, and sustainable supply chains, ensuring businesses remain competitive and responsive to the demands of tomorrow.

Top FAQs

What is the primary benefit of an ERP system for supply chain visibility?

An ERP system provides real-time, centralized access to data across all supply chain functions, offering a single source of truth that significantly enhances visibility into inventory levels, order status, and shipment tracking.

How does an ERP system help in managing inventory?

ERP systems automate inventory tracking, manage stock levels, forecast demand, and optimize reorder points, thereby reducing carrying costs, minimizing stockouts, and preventing overstocking.

Can an ERP system improve collaboration with suppliers?

Yes, many ERP systems offer modules or integrations that facilitate seamless information sharing, joint planning, and performance monitoring with suppliers, fostering stronger partnerships and accountability.

What are the key considerations when selecting an ERP for supply chain management?

Key considerations include evaluating vendor expertise in supply chain, system scalability, integration capabilities with existing technologies, user-friendliness, and the cost-effectiveness of the chosen deployment model (cloud, on-premise, or hybrid).

How does an ERP system contribute to cost reduction in the supply chain?

ERP systems reduce costs by optimizing inventory, improving order fulfillment accuracy, minimizing lead times, identifying inefficiencies in transportation and logistics, and enabling better demand forecasting and procurement planning.